A pocket knife is a compact, foldable knife that is easy to carry. It serves various purposes ranging from everyday tasks to outdoor adventures.

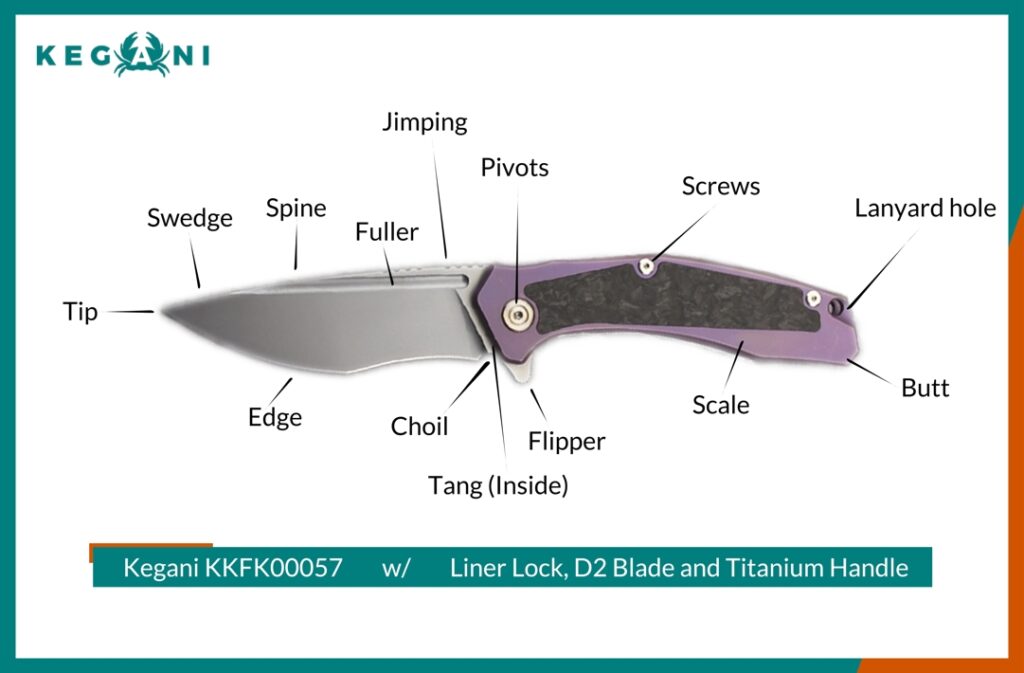

The primary components of a pocket knife include the blade, which is the cutting edge usually made of steel; the handle, providing a secure grip; the pivot, the point where the blade rotates; and the lock, which holds the blade in the open position to ensure safety during use.

A pocket knife might also contain other tools like scissors, tweezers, or screwdrivers, making them a versatile tool. The quality and functionality of these components can vary widely, influencing the overall performance and use-case of the pocket knife.

We’ll delve into the details of each knife part in the upcoming sections. Keep on reading for the nitty-gritty!

Basic anatomy of a pocket knife

Edge

The edge of a knife is arguably its most critical feature, as it directly influences cutting performance and usability. Knife enthusiasts often debate the merits of various edge geometries, including straight edges, serrated edges, and hybrid configurations.

Additionally, the angle of the edge, typically measured in degrees per side, can significantly affect cutting ability and durability, with finer angles offering sharper but less durable edges, while wider angles provide greater durability at the expense of some cutting performance.

Spine

The spine of a pocket knife provides structural support opposite the cutting edge. It ensures blade stability during use, with features like jimping for grip and control. A well-designed spine enhances usability and aesthetics, reflecting craftsmanship and attention to detail.

Tip

The tip of a pocket knife plays a vital role in its cutting capabilities and overall style, which are crucial for various tasks. When discussing different blade shapes, some are characterized by the shape of the tip. For instance, drop point tips offer control and strength, making them ideal for general use. Tanto tips, on the other hand, provide piercing ability and durability, making them suitable for tactical applications. We’ll delve deeper into blade shapes and tips in the following sections.

Butt

Situated opposite the blade’s tip, the butt serves as a counterbalance, enhancing control and balance during use. Enthusiasts appreciate a well-designed butt for its ergonomic qualities, ensuring a comfortable grip and reducing hand fatigue during prolonged use.

Tang

The tang of a pocket knife refers to the portion of the blade that extends into the handle. It is a critical component of the knife’s construction, providing stability, strength, and durability. Enthusiasts often prefer knives with full tang construction, where the metal of the blade extends fully through the handle, offering maximum strength and stability.

While partial tang knives may sacrifice some strength compared to full tang models, they can still offer sufficient durability for everyday tasks.

Swedge

Located on the spine of the blade, the swedge refers to a beveled or angled portion near the tip. This design element serves multiple purposes, including reducing weight and improving balance by removing excess material from the blade’s spine. Additionally, the swedge can enhance the knife’s piercing ability by providing a more acute point.

Fuller

The fuller, also known as a blood groove or a groove. It is a feature found on some knife blades that runs along the spine, typically extending down the center. Contrary to popular belief, the primary purpose of a fuller is not to allow blood to flow more freely when the blade is withdrawn from a wound, but rather to reduce weight without sacrificing structural integrity. By removing material from the blade’s spine, the fuller serves to make the knife lighter and more agile, enhancing its balance and maneuverability during use.

Choil

The choil of a pocket knife refers to the unsharpened portion of the blade near the handle. It serves several important functions that contribute to the knife’s usability and safety.

Firstly, the choil provides a convenient finger rest, allowing the user to choke up on the blade for increased control and precision during detailed cutting tasks. This can be particularly useful when performing intricate work that requires fine motor skills and accuracy.

Additionally, the choil acts as a safety feature by creating a buffer zone between the sharpened portion of the blade and the handle, reducing the risk of accidental contact and potential injury to the user’s fingers.

Screws

Screws are integral components of pocket knives, responsible for securing various parts together to ensure structural integrity and functionality.

Ricasso

The ricasso of a pocket knife refers to the flat, unsharpened portion of the blade between the cutting edge and the handle. It provides a safe area for the user to grip the knife when applying pressure to the blade, especially during tasks that require controlled force or precision. This helps prevent accidental contact with the sharp edge, reducing the risk of injury.

Additionally, the ricasso serves as a transition point between the blade and the handle, creating a seamless junction that enhances the knife’s balance and ergonomics.

Flipper

The flipper is a prominent feature on many modern pocket knives, particularly those with assisted opening mechanisms or flipper deployment systems.

It consists of a protrusion on the back of the blade, typically near the base, that acts as a lever for rapid one-handed opening. To deploy the blade, the user applies pressure to the flipper, causing the blade to swiftly pivot out of the handle and lock into position. This design allows for quick and effortless deployment, making flipper-equipped knives popular among enthusiasts and everyday users alike. Additionally, the flipper serves a dual purpose by also acting as a finger guard when the blade is deployed, enhancing safety during use. Enthusiasts often appreciate well-designed flippers for their intuitive operation and sleek aesthetic, which adds both functionality and style to the knife. Overall, the flipper is a versatile and practical feature that enhances the usability and appeal of a pocket knife.

Start Working with a Professional Now

Handle design

The handle of a pocket knife is pivotal for control and grip during use. It must balance ergonomics with functionality and often comes in a variety of materials such as wood, bone, G-10, carbon fiber, and titanium.

Pivots

The pivot is the point at which the blade rotates when opening or closing the knife. It’s crucial for the smooth operation of the knife. Some knives may even feature adjustable pivot screws, allowing you to fine-tune the blade’s resistance, more on pivots later.

Jimping

Jimping refers to the notched or grooved area on the back spine of the knife handle (and sometimes on the blade) designed to prevent your fingers from sliding. This provides better control when applying pressure during cutting tasks.

Clips

Pocket knife clips are designed for convenient carry. They can be attached in various positions on the handle: tip-up, tip-down, left-handed, or right-handed. Clips must be sturdy, yet not too tight, to facilitate easy access without damaging clothing.

Scale

The scale is the exterior part of the handle that provides grip. Scales come in various materials:

- Wood: Classic and elegant but can be prone to swelling or shrinking. Wood is a more common material for kitchen knives, but not so much with pocket knives.

- Bone: Durable with a traditional feel, yet subject to cracking.

- G-10: A fiberglass-based laminate that is tough, lightweight, and impervious to moisture.

- Carbon Fiber: Strong and lightweight, with a distinctive aesthetic.

- Titanium: Offers strength and corrosion resistance, often found in higher-end knives.

Lanyard hole

This feature allows you to attach a lanyard or keychain to your knife. A lanyard hole can aid in the quick retrieval of the knife from your pocket or can be used to secure your knife to prevent loss.

Types of blades

When it comes to designing a pocket knife, the blade shape is a major decision. There’s a variety of blade shapes tailored for different uses. Your customers might also have their own preferences. Here are some common blade types:

- Flat point: Ideal for scraping and chiseling tasks.

- Drop point: Versatile and strong, suited for slicing and everyday use.

- Tanto point: Angular shape with a strong tip for piercing through tough materials.

- Sheepsfoot: Features a flat cutting edge and a dull back, good for chopping with minimal risk of accidental puncturing.

- Wharncliffe: Similar to the sheepsfoot but with a more pronounced taper towards the tip, providing more control.

- Clip point: With a concave back and a finer tip, it excels in precision tasks like carving or skinning.

- Spear point: Symmetrical shape with a strong point, balanced for both slicing and piercing.

Remember, the blade design should reflect your specific needs. Whether for daily cutting tasks or more specialized work like piercing tough materials. Additionally, when considering a multi-tool pocket knife, you may find a combination of these blade types to handle a variety of situations efficiently.

Opening mechanisms

Pocket knives incorporate various opening mechanisms that enable you to deploy the blade quickly and safely. Understanding these mechanisms helps in selecting a knife that suits your needs.

Openers

Different opening mechanisms may add additional components to a knife. For instance, naturally a button opener will have an added button between the blade and the handle. Some other openers include:

- Thumb stud: A small knob attached to the blade that lets you open the knife using your thumb.

- Thumb hole: An alternative to the thumb stud, requiring you to push your thumb into the hole and apply pressure to open the blade.

Pivot and detent

Underlying the deployment of the blade is the pivot system—the point at which the blade rotates when opening and closing. The smoothness of this motion is often enhanced by washers or bearings placed around the pivot.

- Washers: Flat rings that reduce friction between the blade and the handle during use.

- Bearings: Round elements that facilitate a smoother rotation than washers.

Another integral component of the opening mechanism is the detent. It’s a resistance feature that holds the blade in place when it’s closed to prevent accidental deployment.

When choosing a pocket knife, your preference in opening mechanisms should factor in convenience, ease of use, and maintenance requirements.

Start Working with a Professional Now

Lock types

Pocket knives are equipped with various locking mechanisms to ensure the blade stays in place when open, preventing accidental closure which could lead to injury.

Same with opening mechanisms, different locks may add various components to a regular pocket knife. For example, a liner lock will have a liner in between handle scales that lock the blade in place.

Some common locks include:

- Frame lock: A portion of the knife handle moves inward to lock the blade’s base when unfolded, offering a stable and secure lock-up.

- Liner lock: Similar to the frame lock, but utilizes a thin metal liner within the handle to secure the blade. It’s typically engaged and disengaged with a thumb.

Your pocket knife may feature other locking mechanisms, but the above are among the most common. These ensure that your knife remains safe and effective when you need it the most.

Tips on knife designing

Kegani is a professional OEM knife manufacturer. We have assisted numerous knife designers in bringing their visions to life. If you are dreaming of creating a knife from scratch, we have some suggestions:

- Handle ergonomics: Ensure the handle is comfortable to hold, with a non-slip grip. It should be shaped to fit in a closed fist without causing discomfort during use.

- Additional tools: Consider incorporating other tools such as screwdrivers, can openers, or scissors. Each tool should add value without compromising the knife’s main function.

- Portability: Aim for a lightweight and compact design to ensure it fits comfortably in a pocket. A pocket clip or a lanyard hole can enhance carry options.

- Aesthetics: Your design should be visually appealing to stand out in the market. However, aesthetics should not overshadow functionality.

- Quality control: Continuous testing with your manufacturer for reliability and safety is imperative. Ensure that each knife meets strict quality standards before it reaches the customer.

By following these guidelines, you can design a functional pocket knife that appeals to consumers. Both in utility and design, boosting your prospects in the competitive market. Remember to prioritize balance between form and function to achieve a product that resonates with your target audience.

Design knives with an experienced manufacturer

Understanding what each part of a pocket knife does isn’t just essential for pocket knife enthusiasts, but it’s also vital for aspiring knife designers.

If you’re on the hunt for manufacturers to produce a pocket knife according to your unique design, Kegani, an experienced knife manufacturer, offers complete customization of each knife part through our OEM service. From blade shape to intricate design details, we assist in designing, rendering, and manufacturing the perfect knife tailored to your vision. Contact us now for a free quote!