Gerber is one of the most recognizable names in the knife world, known for producing everything from rugged survival blades to everyday carry folders.

While the brand often highlights its American roots, not all Gerber knives are made in the USA.

In fact, many of its popular models are manufactured in China to meet growing global demand.

In this post, we’ll take a closer look at where Gerber knives are made, how the company balances domestic and international production, and what that means for quality, craftsmanship.

Brief history of Gerber knives

- 1939: Gerber began as an offshoot of an advertising firm when founder Joe Gerber started selling handmade kitchen knives as holiday gifts.

- 1940s–50s: The brand quickly expanded beyond kitchen cutlery into hunting and outdoor knives.

- 1966: Gerber opened a dedicated factory in Tigard, Oregon, the same facility where many of its knives are still made today.

- 1980: Introduced the LST folding knife, one of the first lightweight, one-handed EDC knives, often credited with shaping the modern pocket knife market.

- 1992: Launched the Gerber Multiplier, helping establish the company’s presence in the multi-tool space.

- 1987–present: Acquired by Fiskars (Finland), but continues to operate independently with U.S.-based leadership and operations.

Start Working with a Professional Now

Where are Gerber knives made?

Gerber’s manufacturing is anchored in the United States, with many of its knives and multi-tools produced at the company’s long-standing facility in Portland, Oregon.

This factory, active since the 1960s, remains central to the brand’s identity, especially for premium, military-grade, and select hunting or survival models. Design and engineering also take place at this U.S. location.

That said, a large portion of Gerber’s knives are manufactured overseas, primarily in China. Many of the brand’s entry-level and mid-range models, including popular folders and everyday carry tools, are produced by contract factories abroad.

This allows Gerber to offer a wide product range while maintaining competitive pricing in global markets.

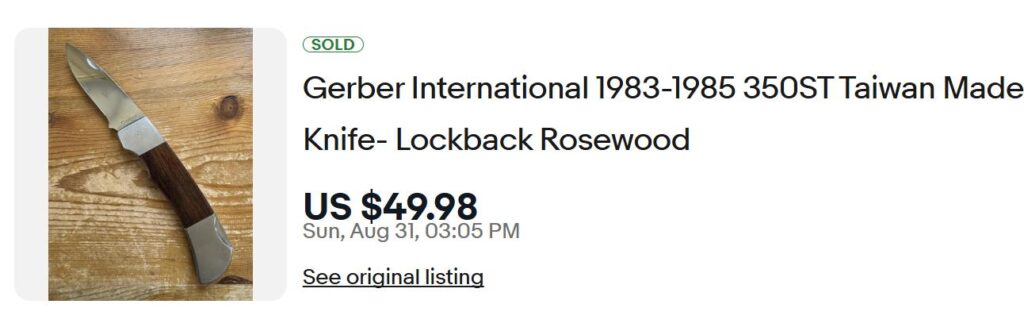

Historically, Gerber also had production in Taiwan under the “Gerber International” label, though that’s less common today.

The company continues to split its production between American-made models and internationally sourced ones, depending on the product type and target market.

Top Gerber knife manufacturing locations

While the Portland plant is the heart of Gerber’s U.S. operations, the company’s manufacturing footprint extends far beyond Oregon.

Below are the key locations where Gerber knives are made today, including both domestic and international sites.

- Portland/Tigard, Oregon (USA): This is Gerber’s primary manufacturing facility. Opened in 1966, the Portland-area plant remains the brand’s central hub for premium production.

Many of Gerber’s flagship fixed blades, multi-tools, and custom knives are made here, with a focus on quality, precision, and American craftsmanship.

The facility combines traditional knife-making values with modern manufacturing technology.

- China: A large share of Gerber’s production takes place in China.

Models like the StrongArm and Torch series are labeled “Made in China” and represent much of the brand’s everyday carry and entry-level range.

These factories help Gerber offer a wider product selection at accessible price points.

Start Working with a Professional Now

- Other regions (e.g. Taiwan, Southeast Asia):

Gerber has also produced knives in Taiwan and other parts of Asia, particularly under its former “Gerber International” label.

While current details are limited, international partnerships continue to support the brand’s global supply chain.

How are Gerber knives manufactured?

Step 1: Steel cutting and shaping

Gerber begins with high-quality steel blanks, which are cut using CNC machines or waterjet technology.

Once cut, each blade is ground top and bottom to achieve the proper thickness before the tang is machined.

Step 2: Heat treatment

After shaping, the blades undergo a proprietary heat-treatment cycle designed to harden the steel and optimize performance.

This step ensures durability and edge retention in both heavy-duty and everyday-use knives.

Step 3: Hand-beveling and sharpening

A skilled craftsman then bevels each blade edge by hand. This step is especially critical for Gerber’s custom and high-end models, where blade geometry and sharpness are held to tight tolerances.

Step 4: Assembly and finishing

Once blades and other components (like handles or locking mechanisms) are ready, the knife is assembled by hand.

For custom orders, laser engraving can be applied before final assembly, allowing for branding, logos, or even personalized messages.

Step 5: Quality control

Gerber follows a multi-step QA process. Assemblers test the fit and feel of each knife, sharpeners ensure the edge is properly honed, and final inspectors conduct visual and functional checks before packaging.

This layered approach helps maintain consistency across both mass-produced and limited-run products.

What other knife makers can learn from Gerber

Gerber’s longevity is the result of smart decisions that balance tradition with market demands.

Here are some takeaways that other knife manufacturers, especially those looking to scale, can learn from:

1) Lean into your origin story

Gerber doesn’t shy away from its history. Its long-standing Portland roots and decades of manufacturing experience are front and center in its branding.

If your brand has a meaningful backstory, use it. Customers and retailers alike value transparency and heritage, it builds trust.

2) Create, don’t just follow product trends

Gerber helped define categories like the modern EDC knife (with the LST) and the multi-tool (with the Multiplier).

Instead of reacting to trends, the brand shaped them.

Even small manufacturers can stand out by offering one distinctive, problem-solving product, especially in saturated markets.

3) Go deep in a niche

From military contracts to outdoor and survival tools, Gerber has earned credibility in specialized markets.

You don’t have to target everyone. Focus on building authority in a niche, whether that’s hunting knives, bushcraft blades, or tactical gear, and become known for doing it better than anyone else.

Start Working with a Professional Now

4) Use local production as a brand advantage

Gerber continues to highlight its U.S.-made models. If you have in-house or local production, promote it.

Even partial domestic assembly can differentiate your brand in a space crowded with generic imports.

5) Think long-term with sustainability

Gerber has publicly committed to turning its Portland plant into a zero-waste facility by 2030.

As sustainability becomes a purchasing factor, brands that take clear, measurable steps will gain an edge, especially with larger retailers and corporate buyers.

If you want more inspiration then we’ve also written posts for other popular knife brands that you can learn from:

- Where are Buck knives made

- Where are Sog knives made

- Where are Spyderco knives made

- Where are Microtech knives made

- Where are WE knives made

- Where are CJRB knives made

- Where are Kizer knives made

- Where are Case knives made

- Where are Benchmade knives made

Final thoughts

Gerber’s story is a clear example of how great knife brands are built, by combining legacy craftsmanship with smart, scalable manufacturing.

From military-grade fixed blades to everyday folders, Gerber has shown what’s possible when quality, consistency, and innovation come together.

If you’re looking to develop your own line of knives, whether custom-designed or private label, Kegani can help bring that vision to life.

Our team supports OEM clients worldwide with expert manufacturing, reliable sourcing, and hands-on guidance from concept to final product.

Whether you need a full-service production partner or want to refine an existing design, Kegani is ready to support your next move. Contact us today to get started.