Choosing the right handle material is a critical decision for any knife seller. Are you caught between the rugged reliability of G10 and the sleek sophistication of carbon fiber? We understand the pressure to make the right choice for your customers and your bottom line.

This article offers a no-nonsense comparison of G10 and carbon fiber handles, tailored specifically for sellers like you. We’ll cover everything from performance to price point, giving you the edge in your sales pitch.

By the time you finish reading, you’ll be equipped to match the right handle to the right customer, maximizing your profits and minimizing returns.

Let’s dive in!

Overview of Carbon Fiber and G10

Both G10 and carbon fiber are popular knife handle materials. G10 is made from layers of fiberglass cloth soaked in resin. It’s tough, waterproof, and resists wear and tear. You can find G10 in many colors and textures.

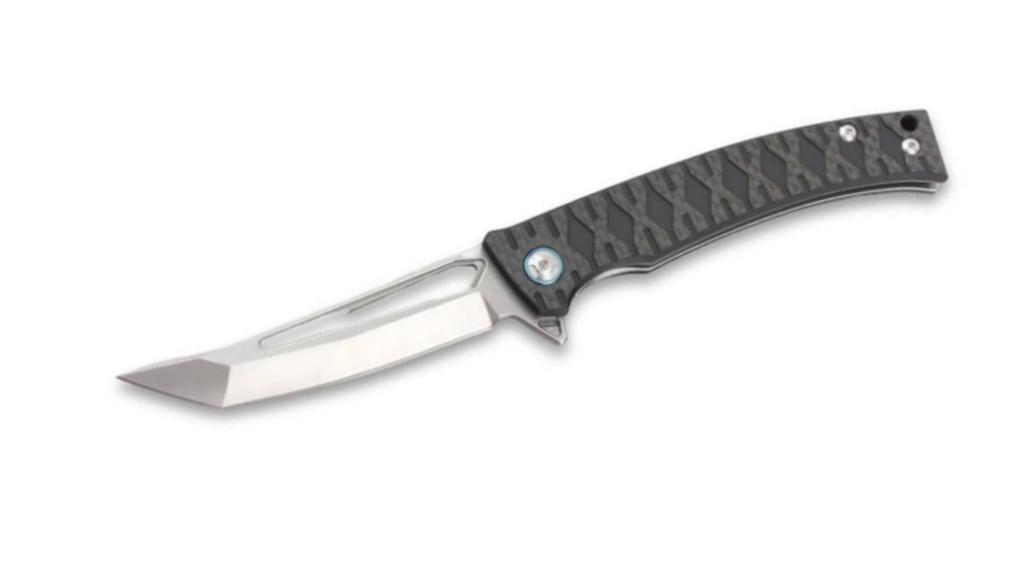

Carbon fiber consists of thin carbon strands set in resin. It’s incredibly strong and lightweight. Carbon fiber handles often have a sleek, high-tech look. While traditionally known for its black appearance, carbon fiber can now be found in various colors.

Both materials started out in aerospace and military uses, now they’re common in knives with various knife blade shapes.

There are other handle materials too. Micarta, Richlite, and FRN each have their own pros and cons. You can learn about those in our other articles.

Carbon Fiber vs G10: Similarities and core differences

Before we delve into the detailed comparison of their user experience aspects such as grip and customization, let’s examine the fundamental similarities and differences:

Similarities

Composite construction:

Both G10 and carbon fiber are high-performance composite materials, meaning they’re made from a blend of fibers and resin. This structure gives them exceptional strength and durability.

Think of it like reinforced concrete: the fibers provide the tensile strength, while the resin binds everything together into a solid, resilient form.

Manufacturing process:

Both materials undergo a similar manufacturing process. Fibers are soaked in resin and then compressed under high heat and pressure.

This ensures the fibers are thoroughly saturated and a tight, layered structure is formed, resulting in a tough, resilient material.

Start Working with a Professional Now

Core differences

The most significant differences between G10 and carbon fiber lie in the type of fibers used and the resulting performance characteristics.

The building blocks:

G10: G10 is primarily composed of 10% glass fiber and 90% epoxy resin. The “10” in G10 indicates that glass fiber accounts for 10% of the material, while the remaining 90% is epoxy resin.

Carbon Fiber: Made from interwoven strands of carbon fibers (60-70%), also bound with epoxy resin (30-40%). This results in an incredibly lightweight material with exceptional strength.

Physical Properties:

Rigidity

Carbon Fiber: Extremely rigid with minimal flex

G10: Rigid but less so than carbon fiber

Temperature Resistance

G10: Functional from -50°C to 140°C

Carbon Fiber: Can withstand -55°C to 180°C, depending on resin

Electrical Properties

G10 is an excellent electrical insulator, often used in electronics, while carbon fiber conducts electricity and might require special treatment in certain applications.

Waterproofing

Both G10 and carbon fiber are waterproof due to the epoxy resin used in their construction, making them suitable for knife handles exposed to moisture.

Workability

G10:Relatively easy to shape and cut using standard woodworking tools, making it versatile for crafting intricate designs.

Carbon Fiber: Requires specialized tools and expertise due to its brittle nature. Precision is key to avoid fraying and ensure a clean, polished finish.

Carbon Fiber vs. G10: Head-to-head comparison

Now, Let’s compare these materials on key factors that directly affect how users interact with their knives:

Weight

Carbon fiber is lighter. It’s about 5 times lighter than steel. G10 is about 10-20% heavier than carbon fiber, but still lighter than many other handle materials.

G10 is at about 1.8 g/cm3. This gives knives a solid, substantial feel in your hand. Carbon fiber is super light at roughly 1.5 g/cm3. It’s perfect if you want a featherweight knife for easy carrying.

Grip

G10 offers excellent grip, especially when textured. You can get it bead-blasted or jimped for even better traction. It’s great for tactical knives that need a secure hold in wet conditions.

Carbon fiber can be slippery when polished. Some textured finishes improve grip, but it’s generally not as tacky as G10.

Strength

Both are strong, but carbon fiber has a better strength-to-weight ratio. It’s incredibly rigid and won’t flex under load.

Durability

G10 is tough as nails. It resists impacts, cracks, and chips like a champ. You’ll often see it on rugged survival knives.

Carbon fiber is strong but can be brittle. A hard drop might crack it, while G10 would likely shrug it off.

Customization and aesthetics

G10 is highly customizable. It offers a wide range of color options, from solid colors to multi-layered patterns. It can be matte or polished, and its texture can range from smooth to rough. This versatility allows G10 to suit various styles, from tactical to everyday carry.

Carbon fiber offers less customization than G10, but its options have expanded in recent years. While traditionally known for its black color with a signature weave pattern, modern manufacturing techniques have introduced more variety.

Colored carbon fiber is now available in shades like blue, red, and green. Some manufacturers have gone further, offering marbled or swirled effects for a more exotic look.

Here’s a quick comparison table:

| Aspect | G10 | Carbon Fiber |

| Grip | Excellent, textured | Can be slick |

| Weight (g/cm3) | 1.8 | 1.5 |

| Durability | Very high | Good, but brittle |

| Customizability | High | Limited, mostly in weave pattern and some color variations |

| Color options | Wide range | Limited, but expanding |

| Aesthetics | Versatile, sleek or rugged | High-tech, premium look |

Understanding the variety of pocket knife uses can help you guide your customers toward the right handle material for their needs.

Carbon fiber vs. G10: Knife applications

Choosing the right knife handle material is crucial for both functionality and customer satisfaction. Let’s delve into how carbon fiber and G10 perform in various knife applications, highlighting where each material excels:

Everyday carry (EDC) knives

- G10: Excels in EDC knives due to its excellent grip, especially with textured finishes. Its durability and resistance to moisture and chemicals make it ideal for everyday use.

- Carbon Fiber: Appealing for EDC due to its lightweight nature and sleek, modern aesthetic. However, its smooth finish might be less grippy than G10, especially in wet conditions. Consider textured carbon fiber options for improved grip.

Kitchen knives

- G10: A practical choice for kitchen knives due to its excellent water resistance and ease of cleaning. Its durability also makes it resistant to scratches and impacts.

- Carbon Fiber: Offers a lightweight advantage, reducing hand fatigue during prolonged use. However, its susceptibility to chipping and potential slipperiness when wet might be drawbacks in a kitchen environment.

Tactical knives

- G10: Dominates in tactical applications due to its superior grip and rugged durability. It can withstand harsh conditions and provide a secure hold even with wet or gloved hands.

- Carbon Fiber: While strong, carbon fiber’s potential slipperiness makes it less ideal for tactical uses where grip is crucial. When choosing a carbon fiber tactical knife, look for models with thoughtful ergonomics or texture to enhance grip.

Outdoor and survival knives

- G10: A top contender for outdoor and survival knives due to its exceptional durability and ability to withstand extreme temperatures and harsh conditions.

- Carbon Fiber: While strong, its brittle nature makes it less suitable for heavy-duty tasks and extreme environments where impacts are likely.

Here are some categories where Carbon Fiber shines:

Gentleman’s folders/dress knives:

- Carbon Fiber: The elegant and refined look of carbon fiber makes it a perfect choice for gentleman’s folders and dress knives. Its lightweight nature also adds to the overall refined feel.

Lightweight EDC/backpacking knives

- Carbon Fiber: When every ounce counts, carbon fiber’s lightweight nature becomes a significant advantage for backpacking and minimalist EDC knives.

Collector’s knives/High-end pieces

- Carbon Fiber: Often used in high-end and collector’s knives due to its premium aesthetic and association with high-performance materials. Its unique weave patterns can add a touch of artistry to the knife.

Sourcing considerations for wholesalers and retailers

When sourcing G10 and carbon fiber handle materials, there are key factors to keep in mind. Quality is crucial – look for suppliers who provide high-grade G10 and carbon fiber that meet industry standards.

Price points vary widely. G10 typically costs less than carbon fiber, with prices ranging from $5-20 per handle for G10 and $20-100+ for carbon fiber. Buy in bulk to get better rates.

Consider your customer base. G10 appeals to budget-conscious buyers, while carbon fiber attracts high-end customers. Stock both to cater to different market segments.

Customization options are important. G10 comes in various colors and patterns, while carbon fiber offers unique visual textures. Choose suppliers who can provide diverse options.

Lead times can differ. G10 production is usually faster, with turnaround times of 2-4 weeks. Carbon fiber may take 4-8 weeks due to its complex manufacturing process, a factor to consider when working with OEM knife manufacturers.

Check for certifications and quality control measures. Reputable suppliers should provide material data sheets and quality guarantees for both G10 and carbon fiber products.

Frequently asked questions

Knife handle materials can be confusing. Let’s clear up some common questions about carbon fiber, G10, and Micarta. We’ll also look at how to find good knife makers for your business.

Carbon fiber vs Micarta vs G10, which is better for knife handle?

G10 is tough and water-resistant. It’s a popular choice for knife handles. G10 can handle heavy use and rough conditions.

Carbon fiber is extremely strong and lightweight. It looks sleek and modern. Many high-end knives use carbon fiber handles.

Micarta is made from layers of cloth and resin. It’s durable and gives a good grip. Micarta handles often have a nice, warm feel in the hand.

Each material has pros and cons. The best choice depends on the knife’s use and your customers’ preferences. Consider offering knives with different handle materials to suit various needs.

How can I find reliable knife manufacturers?

Look for manufacturers with a good reputation. Check online reviews and ask other sellers for recommendations. Quality is key for customer satisfaction and repeat business.

Consider private-label knife manufacturers for custom designs. Many successful knife brands use this approach. It allows you to create unique products for your store.

Don’t dismiss Chinese manufacturers. Many produce high-quality knives. Brands like CIVIVI and Kizer have gained respect in the knife community.

When choosing a manufacturer, ask about their production methods and quality control. Request samples to check the knives yourself. Good communication is crucial for a successful partnership.

Keganico: Your source for quality knives

Looking for top-notch Chinese knives? Keganico has got you covered! We offer a wide range of high-quality blades to meet your needs.

Our knives feature premium materials like G10 and carbon fiber handles. You’ll find options to suit every customer’s preferences and budget.

We pride ourselves on attention to detail. Each knife undergoes rigorous quality control to ensure it meets our high standards. You can trust that the products you receive will impress your customers.

Keganico offers flexible wholesale options to fit your business. Whether you need a small batch or large order, we can accommodate your requirements.

Want to create your own brand? Our private label service lets you customize knives with your logo and packaging. Stand out from the competition with unique products.

For those seeking complete customization, check out our OEM service. We’ll work with you to bring your knife designs to life.

Ready to take your knife business to the next level? Get a free quote today. We’re here to help you succeed in the competitive knife market.