If you’re wondering about the origin of WE Knives, a brand that’s making waves among knife enthusiasts and retailers alike, the answer is straightforward: Yangjiang City, Guangdong Province, China.

Known as the “Knife Capital of China,” Yangjiang has a 1,400-year rich knife-making tradition. It is a global hub for knife production with modern expertise that sets WE Knives apart.

Here’s what you need to know about sourcing from Yangjiang and why it’s a smart move for your business.

Why Yangjiang?

Yangjiang’s significance goes beyond its association with brands like WE Knives—it’s a manufacturing powerhouse with a complete ecosystem for knife production. The city accounts for 70% of China’s knives and scissors, contributing heavily to the global market. Here’s why it stands out:

- Scale of Production: With more than 1,500 businesses, Yangjiang produces millions of knives annually, ensuring a steady supply for sellers.

- Skilled Workforce: Generations of artisans bring expertise to every blade, maintaining high craftsmanship standards.

- Efficient Supply Chain: Local access to raw materials, steel, and packaging reduces costs and lead times.

- Global Recognition: The China (Yangjiang) Knife Fair, a premier event in the industry, attracts thousands of visitors and exhibitors from around the world. It’s a testament to Yangjiang’s status as the “Knife Capital” and a hub for innovation and trade.

For small and medium-sized sellers, this means access to a variety of manufacturers offering OEM services, making it easier to source custom knives tailored to your brand.

What makes WE knives special?

WE Knives leverages Yangjiang’s strengths while pushing beyond stereotypes about “Made in China” products. They use premium materials like:

- CPM-20CV and S35VN steel from the US for blades that are tough, sharp, and corrosion-resistant.

- Carbon fiber and other high-quality handle materials for durability and comfort. Curious about options? Explore our Ultimate Guide to Knife Handle Materials.

Their quality control is equally impressive. Every knife undergoes multiple inspections before leaving the factory, including a “white-glove cleaning” process to ensure it’s flawless. Yangjiang even has a national knife quality testing center, and WE Knives meets these high standards. For retailers, this translates to:

- Fewer returns

- Higher customer satisfaction

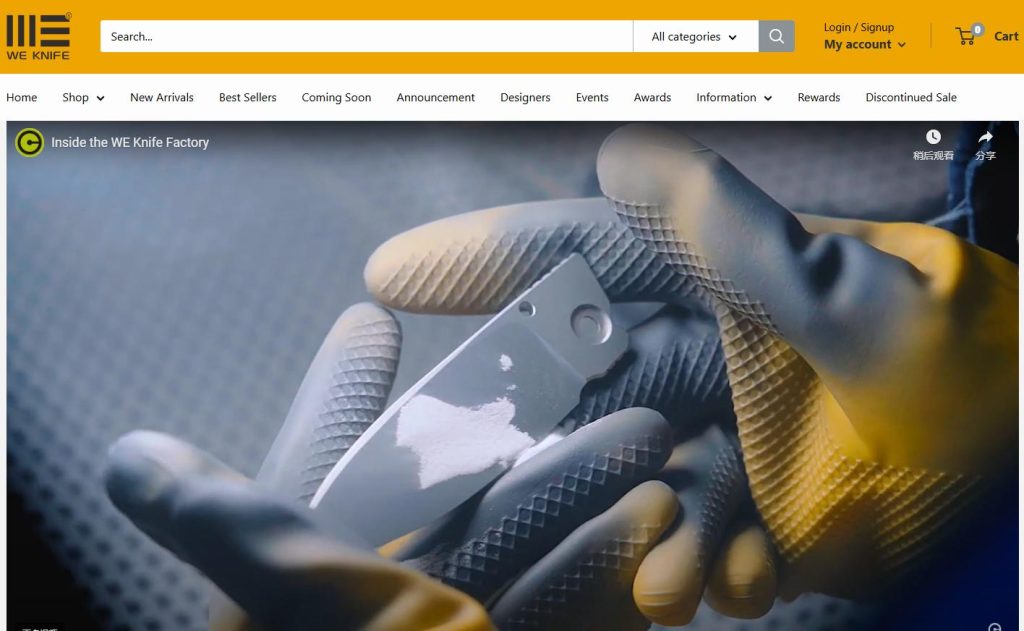

How are We knives made?

WE Knives’ production process is a seamless blend of tradition and modern technology. Whether collaborating with renowned global designers or developing in-house, each knife is crafted to align with international trends. The manufacturing steps include:

- Material Selection: High-quality steel and handle materials are chosen based on the knife’s intended use.

- Forging and Heat Treatment: Blades are forged and treated (often via vacuum heat treatment) for durability and edge retention.

- Grinding and Assembly: Handles are polished and fitted with precision, often by hand, for ergonomic design.

- Quality Checks and Sharpening: Each knife is inspected repeatedly and sharpened before shipment.

- Want a closer look? Check out How Are Kegani Knives Made: Detailed Manufacturing Process.

Start Working with a Professional Now

Overcoming the challenges of sourcing in China

Sourcing in China sounds appealing, but you might be thinking:

- How do I handle the language barrier?

- What about complex logistics?

- Who deals with the import regulations?

Don’t worry—we’ve got you covered. Kegani Knives has extensive experience working with international partners and offers full English support. Even better, if you prefer a hassle-free experience, our procurement team can handle everything for you, including:

- Negotiations

- Quality inspections

- Logistics

- Customs documentation

New to bulk buying? Our How to Bulk Purchase Wholesale Pocket Knives guide walks you through the process step-by-step.

Why source from Kegani?

For small and medium-sized sellers, Kegani offers compelling advantages:

- Cost Savings: Lower production costs mean better margins without compromising quality.

- Customization: With 10 years of expertise in the region, we’ve refined our OEM services and private labeling capabilities. Whether you’re looking for a distinctive knife design or branded packaging, we can tailor our offerings to reflect your brand’s unique identity and help you stand out in the market.

- Diverse Options: Whether it’s outdoor blades or everyday carry knives, Kegani has it all. See more in our 15+ Pocket Knife Blade Shapes: A Detailed Breakdown.

Ready to get started? Contact us for a quote and see how Yangjiang can work for you!

Read More

Want to learn how other big brands make their knives? Check these out: